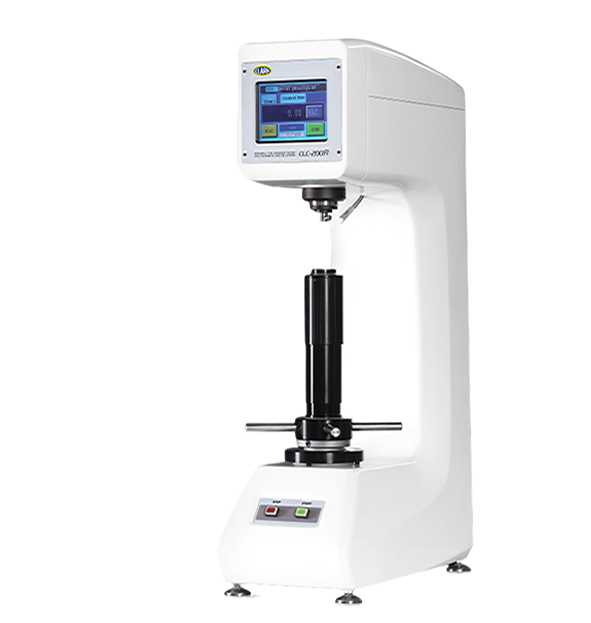

CLC-200R Rockwell-Type Hardness Tester

Fully-automatic load-cell feedback system

CLC-200R Hardness Tester

The Clark CLC-200R is one of the most versatile and easy to use Rockwell type testers available. It uses direct loading, state of the art load cell technology and direct linear displacement that’s activated by simple touch-screen operation. All Rockwell scales, regular and superficial, are fully automatic. And errors have virtually been eliminated by removing the use of knobs and stacking of weights typically associated with most testers. Simply input the scale on the touchscreen and let the tester do the rest.

Special Features

- Fully-automatic load-cell feedback system

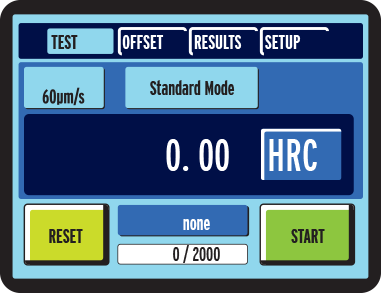

- Vivid color LCD display with one-touch operation

- Performs 30 different “Rockwell” (Regular and Superficial) and light load Brinell tests

- Direct load method. Load-cell feedback/direct linear displacement measurement

- Selectable minor/major load combinations (3 to 200Kg)

- Up to 2000 point data memory capacity

- One piece, heavy-duty cast housing with enclosed load cell

- Complies with ASTM & ISO 17025 Standards

ITEMS | CLC 200R | |

| ROCKWELL-TYPE | BRINELL | |

| Minor Load | 3 (29.42) 10kgf (98.07 N) | |

| Test Load | 15 (147.1), 30 (294.2), 45 (441.3), 60 (588.4), 100 (980.7), 150 kgf (1471 N) | 6.25 61.29), 7.81 (76.61), 10 (98.07), 15.62 (153.2), 20 (196.1), 25 (245.2), 30 (294.2), 31.25 (306.5), 40 (392.3), 62.5 (612.9), 100 (980.7), 120 (1177), 125 (1226), 187.5 kgf (1839 N) |

| Minor Load Position Setting | Automatic setting (electronic sound monitoring) | |

| Flexible Setting | Available 2 load setting within Min. 3kgf (29.42N) and Max. 200kgf (1961N) | |

| LOAD CONTROL | Automatic (loading, holding, removing method) | |

| TRAVEL OF LOAD SHAFT | 8mm Maximum | |

| LOADING SPEED | Min: 200mm per sec / Max: 140μm per sec. / 13s per cycle | |

| DWELL TIME | 1~999 sec (Key entry in units of seconds) | |

| RESOLUTION | Display: either 0.1 or 0.01HR | |

| PLASTIC MEASUREMENT | Available load control method conforming to ASTM D 785 | |

| HARDNESS CONVERSION | Hardness conversion capable in compliance with ASTM (E-140), and JIS | |

| OK/NG CRITERIA | Upper and lower limits setting and OK/NG display (HR 0 to 130, min. 0.1 hardness setting) | |

| SELF DIAGNOSIS | Troubleshoot display for motors and switches | |

| SCALE DISPLAY | C, D, A, G, GW, B, BW, F, FW, K, KW, E, EW, H, HW, P, PW, M, MW, L, LW, V, VW, S, SW, R, RW, 15N, 30N, 45N, 15T, 15TW, 30T 30TW, 45T, 45TW, 15W, 15WW, 30W, 30WW, 45W, 45WW, 15X, 15XW, 30X, 45XW, 15Y, 15YW, 30Y, 30YW, 45Y, 45YW | |

| HR DATA CORRECTION | 5 Points max on HR, offset on HR, HR on convex cylinders, HRC on convex round surfaces (Complies w/ ASTM E 18 / JIS Z 2245) | |

| HR DATA EDITING | Data editing / statistic data (test times/Max./Min./mean/range/Std. deviation dispersion) / graph and histogram display | |

| MAX. INDENTATION DEPTH | Detection and output of maximum indentation depth | |

| SPECIAL TEST MODE | Detection and memory of the displacement of the Load & indentation depth upon loading. (Optional output to PC) | |

| BRINELL TEST MODE | Display HB hardness based on depth of indentation (ASTM E 103) | |

| OUTPUT SIGNAL | RS232C (baud rate: 300~19200, factory setting/1200 bps) & CENTRONICS | |

| DATA PRINT OUT MODE | HR Value, HR & conversion, HR & depth of indentation, HR & OK-NG criteria, HR & stat, HR, mean & OK-NG criteria,conversion data, conversion & OK-NG criteria, conversion & statistics, conversion, mean & OK-NG criteria, maximum depth of indentation | |

| ILLUMNIATION LIGHT | LED | |

| MAX. HEIGHT X DEPTH | 10" (255mm) X 6.7" (170mm) | |

| ACCURACY | Conforms to tolerances per ASTM E 18 / ASTM E 140 / ASTM D 785 / ISO 6505-2 / ISO 6508-2 / ISO6506-2 | |

| DIMENSIONS | 8" (220mm) x 18" (465mm) x 32" (810mm) | |

| WEIGHT | Aprx. 220 Lbs / 99.7 kg | |

| POWER SUPPLY | 120 VAC 1Ø 2A / (AC 100~240V) please specify | |

STANDARD ACCESSORIES | ||

| Hardness Standards: HRC, HRBW, HR30N, HR30TW | 1ea. | |

| Diamond Indenter | 1 “C” & “N” | |

| 1/16" Carbide Ball Indenter | 1 | |

| V-Anvil 1 1/2" (40mm) | 1 | |

| Flat Anvil 2 1/2" (60mm) | 1 | |

| Machine Cover, Accessory Box, Manual, Leveling Leg Set | ||